Technology

QA Center

With an area of 700 square meters, Kayson’s QA Center is mainly divided into two parts: physical and chemical laboratory(P&C Lab) and microbiological laboratory, which can meet the needs of testing for various quality indicators of sanitary products.

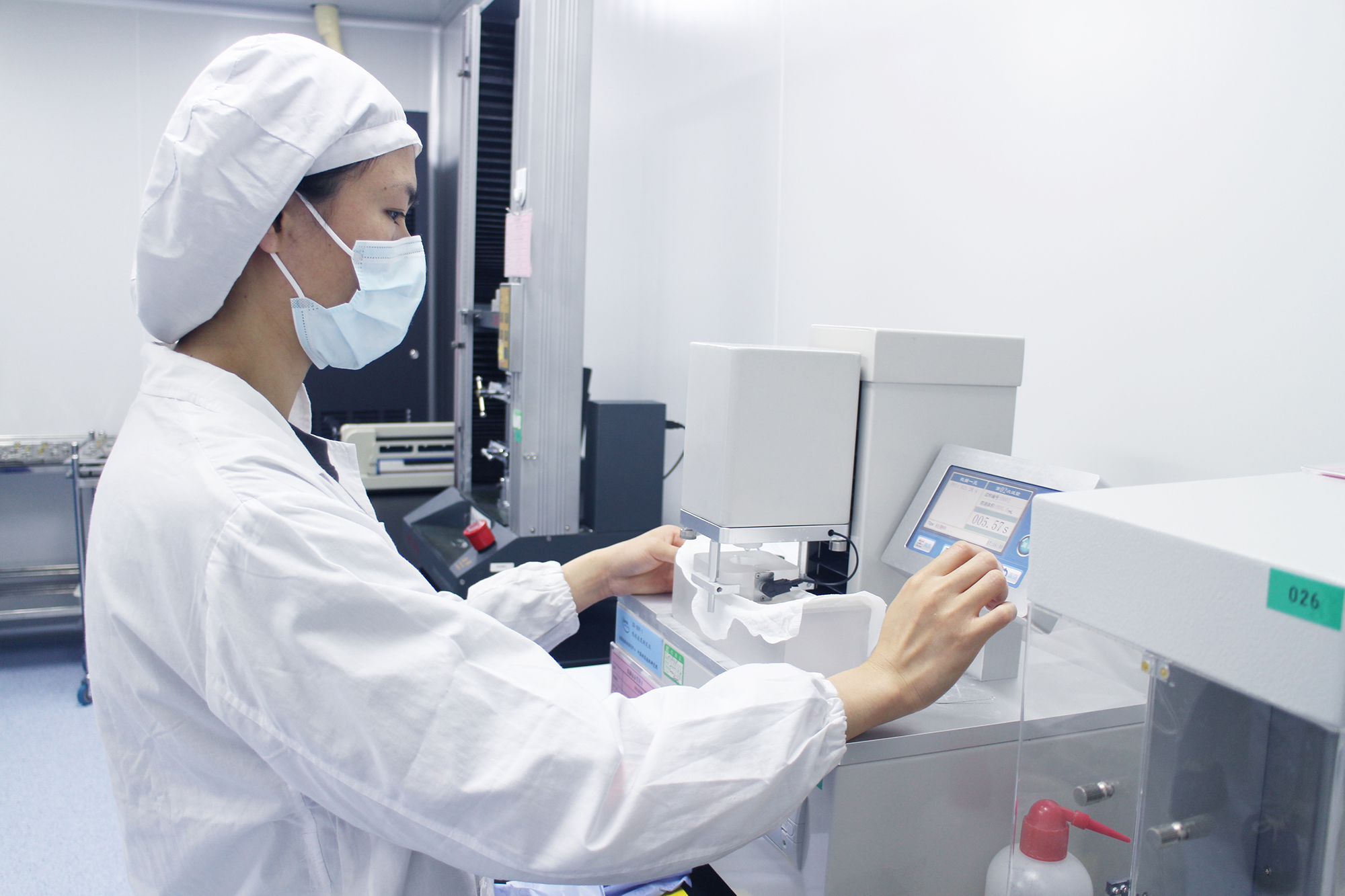

The P&C Lab is designed in a simple and exquisite manner. It is divided into two areas: physical and chemical testing of finished products and physical and chemical testing of raw materials. The entire space is equipped with the temperature-controlled ventilation system, and the tap water and pure water supply system.

The P&C Lab has various precision instruments for testing sanitary products, including sanitary napkin absorption speed tester, liquid permeability tester, friction coefficient tester, etc.

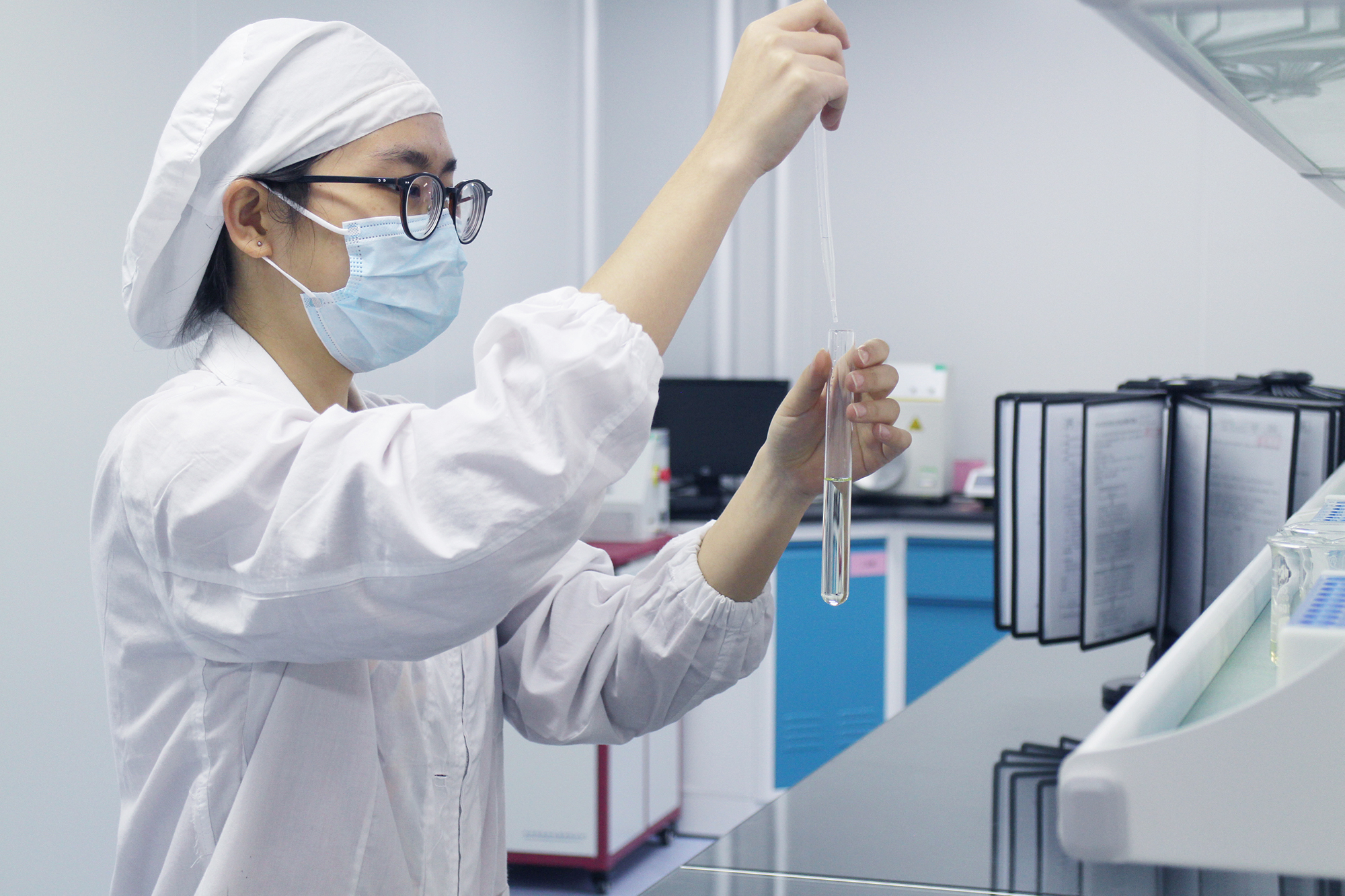

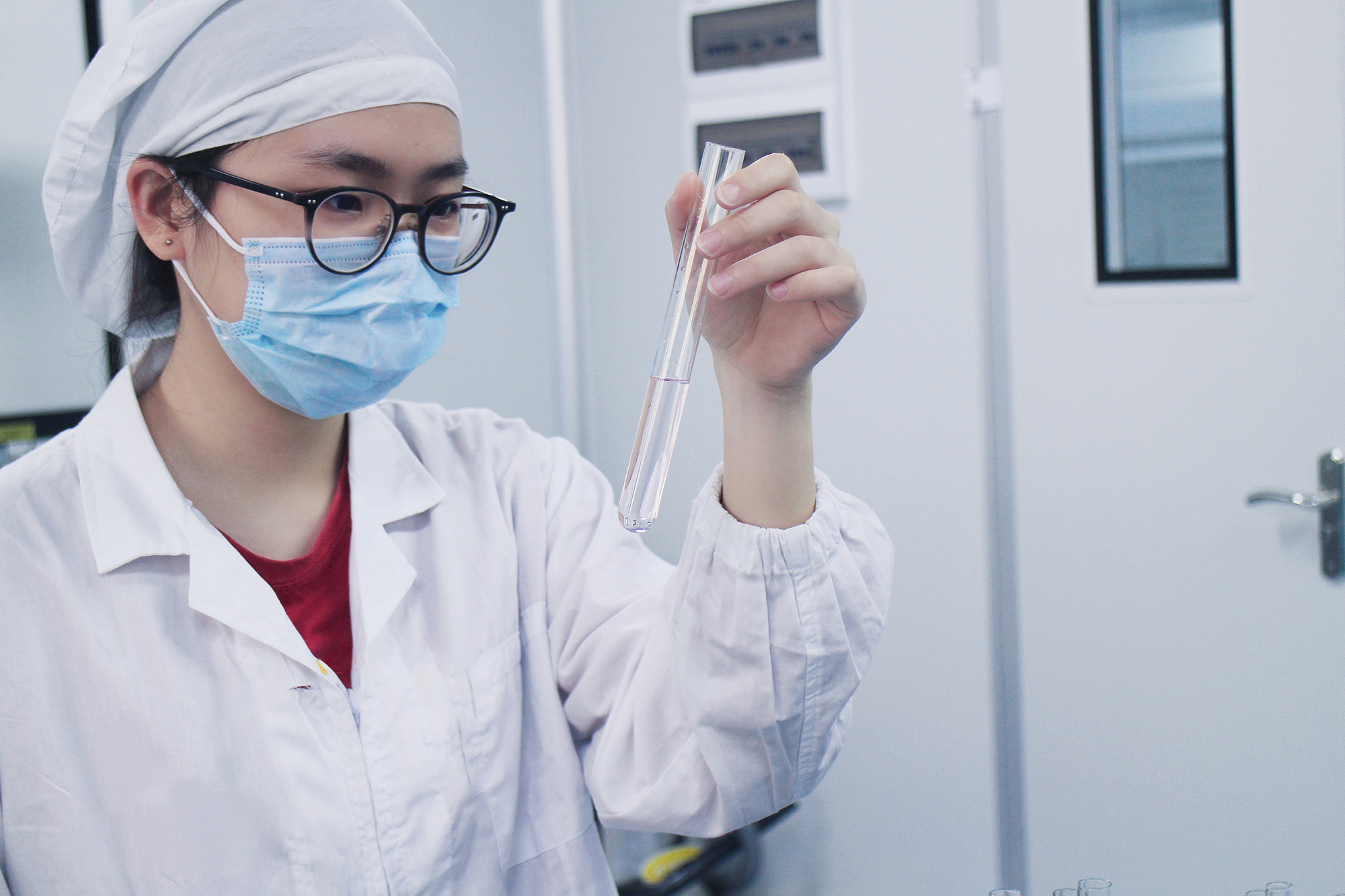

The microbiological laboratory is a self-contained area, which is only accessible by relevant personnel. It is divided into washing room, preparation room, storage room, culture room, micro-inspection room and standard strain operation room. The micro-inspection room is a class 100,000 cleanroom for testing the microbial content of products and materials. The standard strain operation room is used to complete the operation of standard strains and the detection of pathogenic bacteria. Bacteria detection can be accomplished within 3 working days, and fungus detection can be done within 7 working days at fastest.

In addition, the QA Center also has ultraviolet disinfection lamps to disinfect the space regularly and effectively to maintain highly clean.

The P&C Lab is designed in a simple and exquisite manner. It is divided into two areas: physical and chemical testing of finished products and physical and chemical testing of raw materials. The entire space is equipped with the temperature-controlled ventilation system, and the tap water and pure water supply system.

The P&C Lab has various precision instruments for testing sanitary products, including sanitary napkin absorption speed tester, liquid permeability tester, friction coefficient tester, etc.

The microbiological laboratory is a self-contained area, which is only accessible by relevant personnel. It is divided into washing room, preparation room, storage room, culture room, micro-inspection room and standard strain operation room. The micro-inspection room is a class 100,000 cleanroom for testing the microbial content of products and materials. The standard strain operation room is used to complete the operation of standard strains and the detection of pathogenic bacteria. Bacteria detection can be accomplished within 3 working days, and fungus detection can be done within 7 working days at fastest.

In addition, the QA Center also has ultraviolet disinfection lamps to disinfect the space regularly and effectively to maintain highly clean.

R&D Center

Research and development of products plays a vital role in the production process. Kayson boasts a first-class product research and development team, who has been providing OEM/ODM product customization services for well-known domestic and foreign brands.

Kayson is equipped with a professional visual design team delved into market research to develop sanitary napkin products that meet the needs of the brands based on the characteristics of the products.

In order to meet the various needs of the brands, we have also built a small chemical research and development team, which is responsible for the safe and reliable conversion of natural plants into healthy and effective materials. Extracts from natural plants such as chamomile, TMC prescription, and tea polyphenols can be added to the products according to needs.

The length, fabric, structure, and crafts of the products can all be customized by our R&D team. From product design to finished product, it only takes ONE month at the fastest.

Kayson is equipped with a professional visual design team delved into market research to develop sanitary napkin products that meet the needs of the brands based on the characteristics of the products.

In order to meet the various needs of the brands, we have also built a small chemical research and development team, which is responsible for the safe and reliable conversion of natural plants into healthy and effective materials. Extracts from natural plants such as chamomile, TMC prescription, and tea polyphenols can be added to the products according to needs.

The length, fabric, structure, and crafts of the products can all be customized by our R&D team. From product design to finished product, it only takes ONE month at the fastest.

Advanced Equipment

In order to achieve efficient production of products with high quality, the workshops are equipped with systematic disinfection equipment to strictly control the production environment in the workshops. With a elaborative layout, the seven production workshops in the factory become the home to 68 fully automatic high-speed production lines, including production lines for sanitary napkin and baby diapers.

In 2019, for further improvement of production efficiency, Kayson has introduced Zuiko’s sanitary napkin production equipment from Japan, becoming the first enterprise in Guangdong Province to introduce this Japan-based company’s production line. With a total investment of over 100 million yuan, Kayson has possessed industry-leading technology.

In 2019, for further improvement of production efficiency, Kayson has introduced Zuiko’s sanitary napkin production equipment from Japan, becoming the first enterprise in Guangdong Province to introduce this Japan-based company’s production line. With a total investment of over 100 million yuan, Kayson has possessed industry-leading technology.